Activated Charcoal

Activated Charcoal Specification

- Poisonous

- Non-poisonous

- Purity

- 99%

- Physical Form

- Powder

- Taste

- Tasteless

- Storage

- Store in a cool, dry, and well-ventilated area, keep container tightly closed

- Shelf Life

- 3 years

- Application

- Water purification, air filtration, medical detoxification, industrial processes, gold purification

- EINECS No

- 231-153-3

- Solubility

- Insoluble in water

- Shape

- Amorphous

- Ph Level

- Neutral (pH ~7)

- Usage

- As adsorbent in filtration systems, medicinal uses, odor control

- CAS No

- 7440-44-0

- Properties

- Highly porous, odorless, tasteless, insoluble in water, large surface area, high adsorption capacity

- Product Type

- Activated Charcoal

- Molecular Weight

- 12.01 g/mol

- Grade

- Industrial Grade

- Molecular Formula

- C

- HS Code

- 38021000

- Structural Formula

- C

- Refractive Rate

- 1.55

- Density

- 0.44 Gram per cubic centimeter(g/cm3)

- Appearance

- Black fine powder

- Melting Point

- Sublimes at 3915C

- Smell

- Odorless

- Ingredients

- Carbon (from wood, coconut shell, coal)

- Packaging

- 25 kg or 50 kg HDPE bags

- Hardness

- >95%

- Iodine Number

- 900-1200 mg/g

- Mesh Size

- 100 to 325 mesh

- Ash Content

- <4%

- Chlorine Removal Efficiency

- High

- Colour Removal Capacity

- Excellent

- Bulk Density

- 350-600 kg/m³

- Porosity

- High

- Surface Area

- 800-1200 m²/g

- Moisture Content

- <5%

Activated Charcoal Trade Information

- Minimum Order Quantity

- 500 Grams

- FOB Port

- Nhava- Sheva, India

- Payment Terms

- Cheque, Cash Advance (CA)

- Supply Ability

- 2 Grams ton Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, South America, Eastern Europe, Middle East, Africa, Central America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 14001 : 2015 ISO 9001 : 2008 OHSAS 18001 : 2007 WHO GMP

About Activated Charcoal

Over the years, we have emerged as one of the leading organizations engaged in offering Activated Charcoal. It has oxygen added to it to increase its porosity, thereby, adding to its surface area. Charcoal is used to remove chemicals, toxins and gases. Offered charcoal is perfect options for water purification systems and fish tank filtering systems. We make available this Activated Charcoal for clients in different quantity packaging options. Also, we offer this charcoal at pocket friendly prices.

Features:

- Highly porous

- Longer shelf life

- Resistant to acid

Product Specifications:

- Synonym: Charcoal activated

- Special Grade (acid washed) 5 kg

- MB Value 240 25 kg

- Substance soluble in ethanol < 0.2%

- Substances soluble in HCl <1.0%

- Chloride(Cl) <0.01%

- Sulphate(SO4) <0.01%

- Heavy metals(as Pb) <0.005%

- Iron(Fe) <150 ppm

- Loss on drying(120oC) <8%

- pH Value 6.5 to 7.5

- Methylene blue value 240

- CAS NO. 7440-44-0 Un No. NR TARIFF : 3802 10 00Empirical Formula (Hill Notation): C

- Molecular Weight: 12.01

- CAS Number: 7440-44-0

Superior Adsorption for Industrial Applications

Activated Charcoals extensive surface area and high porosity ensure exceptional adsorption of impurities and contaminants, making it indispensable in water purification, odor control, and medical detoxification processes. Its purity and hardness allow for reliable performance in demanding filtration and purification systems. Suitable for various industries, from gold purification to air filtration, it solves complex contamination challenges efficiently.

Quality and Safety Assured

This activated charcoal is non-poisonous, odorless, tasteless, and characterized by a neutral pH, making it safe for a broad range of industrial and medicinal uses. Manufactured following stringent quality standards, it maintains low ash (<4%) and moisture content (<5%), ensuring consistency and effectiveness. Its insolubility in water supports stability in different applications, while its packaging preserves shelf life and product integrity.

FAQs of Activated Charcoal:

Q: How is activated charcoal with a mesh size of 100 to 325 mesh typically used?

A: Activated charcoal with this fine mesh size is primarily used as an adsorbent in water and air filtration systems, industrial purification processes, color removal in chemical manufacturing, and for detoxification in medicinal settings. The fine particle size allows for maximum surface area exposure, enhancing adsorption efficiency.Q: What makes this activated charcoal effective for chlorine and color removal?

A: Its high porosity and extensive surface area (8001200 m/g) enable it to adsorb a large amount of contaminants, including chlorine and color-causing molecules. The high iodine number (9001200 mg/g) further indicates its superior adsorption capacity, leading to excellent purification results in both water and industrial uses.Q: When should activated charcoal be replaced in filtration systems?

A: Activated charcoal should be replaced when its adsorption capacity is exhausted, evident by diminished contaminant removal efficiency or breakthrough of impurities. Replacement intervals depend on the contaminant load and the systems usage frequency. Regular monitoring ensures consistent purification performance.Q: Where is this activated charcoal manufactured and supplied?

A: This activated charcoal is manufactured and supplied by dealers, exporters, manufacturers, retailers, suppliers, and traders based in India. It is distributed worldwide for various industrial and commercial applications, ensuring broad accessibility.Q: What is the recommended storage process for this product?

A: To preserve quality and adsorption capacity, store the activated charcoal in a cool, dry, well-ventilated area. Keep the HDPE bag containers tightly closed to prevent moisture uptake and contamination, which can affect performance and shelf life.Q: How does the high hardness (>95%) benefit the usage of activated charcoal?

A: High hardness ensures the powder maintains structural integrity during handling, transport, and use, reducing dust generation and attrition. This maximizes efficiency in filtration systems and prolongs operational lifespan, saving costs on maintenance and replacement.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Specialty Chemicals Category

ACTIVATED CHARCOAL AR

Price 490 INR

Minimum Order Quantity : 100 Grams

Smell : Other, Odorless

Solubility : Insoluble in water

Usage : Used for adsorption experiments and analytical testing

Appearance : Black fine powder

Ammonium Molybdate

Price 100-500 INR / Kilograms

Minimum Order Quantity : As Per Requirement Kilograms

Smell : Other, Odorless

Solubility : Soluble in water

Usage : Laboratory reagent, catalyst, pigment, corrosion inhibitor

Appearance : White crystalline powder

iso-PROPYL ALCOHOL

Smell : Other, Alcohollike, strong odour

Solubility : Miscible with water, soluble in many organic solvents

Usage : Cleaning, disinfection, solvent in chemicals, laboratories, and industries

Appearance : Clear colorless liquid

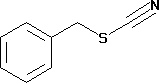

Benzyl Thiocyanate

Smell : Other, Characteristic odor

Solubility : Insoluble in water, soluble in organic solvents

Usage : Laboratory reagent and intermediate

Appearance : Clear to pale yellow liquid

"Only deals in retail accepting orders upto 500ml only".

|

ALPHA CHEMIKA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry