ALUMINIUM BORATE

ALUMINIUM BORATE Specification

- Storage Instructions

- Store in a cool, dry place in a tightly closed container

- Molecular Formula

- Al2O3B2O3 (commonly written as Al18B4O33 or Al2(BO3)3 depending on polymorph)

- Molecular Weight

- 143.58 g/mol

- Flash Point

- Non-Flammable

- Purity

- 99%

- Packaging Type

- Bag / Drum / Customized Packaging

- Physical State

- Powder

- Boiling point

- Not Applicable / Decomposes

- Melting Point

- Above 1100C (depends on polymorph, typically 12001205C)

- Shelf Life

- 24 months (when properly stored)

- Size

- Customizable (standard: fine powder)

- Usage

- Research, Industrial Synthesis, Ceramics manufacturing

- Density

- 2.83 Gram per cubic centimeter(g/cm3)

- Ph Level

- Neutral

- CAS No

- 11121-16-7

- Grade

- Technical Grade

- Type

- Industrial Lab Chemicals

- Application

- Used in ceramic composites, refractory materials, glass formation, and as a flame retardant

- Appearance

- White Powder

- Purity(%)

- 99%

- HS Code

- 28401990

- Color

- White

- Surface Area

- 1525 m/g (for nanostructured grade)

- Particle Size

- <10 micron (standard); nano sizes available

- Solubility

- Insoluble in water

- Refractive Index

- 1.635

- Compatibility

- Compatible with most inorganic binders

- Odor

- Odorless

- Stability

- Stable under recommended storage conditions

ALUMINIUM BORATE Trade Information

- Minimum Order Quantity

- 500 Grams

- FOB Port

- Nhava- Sheva, India

- Payment Terms

- Cash Advance (CA), Cheque

- Supply Ability

- 2 Grams ton Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 14001 : 2015 ISO 9001 : 2008 OHSAS 18001 : 2007 WHO GMP

About ALUMINIUM BORATE

ALUMINIUM BORATE

| aluminum,borate | |

| CAS No.: | 11121-16-7 |

|---|---|

| Synonyms: |

|

| Formula: | AlBH3O3 |

| Exact Mass: | 88.99910 |

| Molecular Weight: | 88.81460 |

Exceptional Material for Advanced Ceramics

Aluminium Borate is specifically formulated for demanding industrial applications, especially within ceramics, glass manufacturing, and refractory sectors. Its high purity and customizable particle sizes-including nano grades with significant surface area-enable precise control in advanced material synthesis. The product's thermal stability and compatibility with most inorganic binders ensure reliable results and expanded application possibilities.

Safe Handling and Long Shelf Life

This material is both non-flammable and stable, provided it is stored in a cool, dry place within tightly sealed containers. The product maintains its quality and strength for up to 24 months without significant degradation. Customizable packaging options, from bags to drums, cater to varied usage volumes and handling requirements across research, manufacturing, and trading environments.

FAQ's of ALUMINIUM BORATE:

Q: How should Aluminium Borate be stored to maintain its stability and shelf life?

A: Aluminium Borate should be stored in a cool, dry area, tightly sealed in its original container. Under these recommended conditions, the product remains stable with a shelf life of up to 24 months.Q: What are the main industrial applications of Aluminium Borate?

A: Aluminium Borate is primarily used in the production of ceramic composites, refractory materials, glass formation, and as a flame retardant due to its high melting point, thermal stability, and inertness.Q: Where is Aluminium Borate commonly used and who supplies it?

A: This compound is widely utilized in research laboratories, ceramics manufacturing, and industrial synthesis. It is supplied, manufactured, exported, and retailed by various dealers and traders across India.Q: What are the benefits of using Aluminium Borate in ceramic and glass industries?

A: Aluminium Borate enhances the strength, durability, and thermal shock resistance of ceramic and glass products, making them suitable for high-performance and specialized applications.Q: What grades and particle sizes are available for Aluminium Borate?

A: The standard grade offered is Technical Grade with 99% purity. Particle sizes are customizable, with standard fine powder (<10 micron) and nano-structured sizes (surface area 15-25 m2/g) available upon request.Q: Is Aluminium Borate safe to handle and does it have any specific hazards?

A: Aluminium Borate is classified as non-flammable and odorless, and it does not pose significant risks when handled with standard laboratory or industrial precautions. Ensure containers are well-sealed to prevent contamination or moisture ingress.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory Chemicals Category

ALUMINIUM AMMONIUM SULPHATE AR

Price 335 INR

Minimum Order Quantity : 500 Grams

Type : Other, Inorganic Salt

Grade : AR (Analytical Reagent)

Purity(%) : 99%

Application : Laboratory, Analytical, Industrial

ALUMINIUM MAGNESIUM SILICATE

Price 160 INR / Kilograms

Minimum Order Quantity : 25gm Kilograms

Type : University Lab Chemicals

Grade : Tech Grade

Purity(%) : 99%

Application : Pharmaceutical, Cosmetics, Industrial

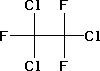

Trichlorotrifluoroethane Chemical

Minimum Order Quantity : 500 Milliliters

Type : Other, Organic Chemical

Grade : Laboratory Grade

Purity(%) : 99%

Application : Solvent, cleaning agent, refrigerant

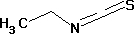

Ethyl isothiocyanate

Minimum Order Quantity : 500 Milliliters

Type : Industrial Lab Chemicals

Grade : Industrial

Purity(%) : 99.99

Application : Lab Chemicals

"Only deals in retail accepting orders upto 500ml only".

|

ALPHA CHEMIKA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry