Hydrofluoric Acid 40%

Hydrofluoric Acid 40% Specification

- Boiling point

- Approximately 108C (40% solution)

- Smell

- Pungent, Irritating Odor

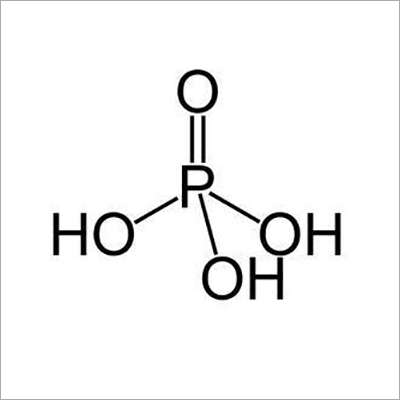

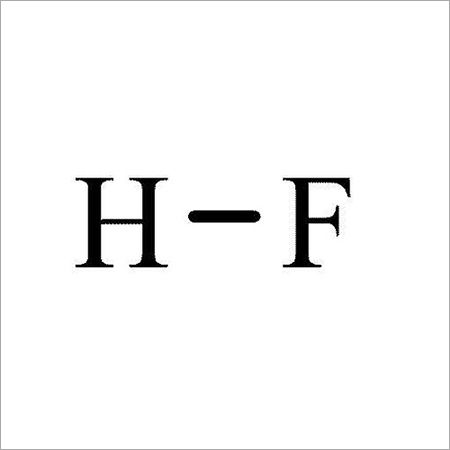

- Structural Formula

- HF

- HS Code

- 28111100

- Molecular Weight

- 20.01 g/mol

- Refractive Rate

- 1.25 (approximate)

- Molecular Formula

- HF (aq)

- Taste

- Not Applicable (Toxic & Corrosive)

- Classification

- Inorganic Acid

- Inorganic Acid Types

- Hydrofluoric Acid

- Purity

- 40%

- Application

- Glass Etching, Metal Cleaning, Electronics Industry, Chemical Synthesis

- Appearance

- Colorless, Fuming Liquid

- EINECS No

- 231-634-8

- Other Names

- Hydrogen Fluoride Solution

- Usage

- Used as an industrial reagent, in etching glass, cleaning metals, and in other specialized chemical applications

- Melting Point

- -83.6C

- Density

- 1.13 Gram per cubic centimeter(g/cm3)

- Solubility

- Miscible with Water

- Raw Material

- Hydrogen Fluoride, Water

- Storage Conditions

- Cool, ventilated area, away from incompatible substances such as glass and strong bases

- pH Value

- Less than 2.0 (Very Acidic)

- Stability

- Stable under normal conditions, reacts with glass and metals

- Corrosivity

- Highly corrosive to skin, eyes, and mucous membranes

- Transport Hazard Class

- 8 (Corrosive)

- Vapor Pressure

- Noted for fuming; emits hazardous vapors at room temperature

- Packaging

- Supplied in Plastic or Teflon Containers

- Hazard Identification

- Corrosive, Toxic, Causes Severe Burns

- UN Number

- UN1790 (Hydrofluoric Acid Solution)

- Shelf Life

- 24 Months (if stored properly in airtight containers)

About Hydrofluoric Acid 40%

We are a reputed organization that caters to the diversified requirements of clients by offering our clients Hydrofluoric Acid 40%. This chemical is known for its exceptionally high chemical purity and far superior kinetics and reaction mechanics. We use finest quality compounds, sourced from trusted vendors to process this chemical. Hydrofluoric Acid 40% is highly effective in analysis of trace metals. It is used in mining, chemical, glass manufacturing and ceramic industry.

Features :

- Colorless solution

- Miscible in water

- Longer shelf life

Composition :

| Tests | Specifications | Results |

| Description | Colourless to brown fuming liquid | Colourless to brown fuming liquid |

| Assay (Min) | 55.0% | 55.93% |

| Arsenic (As) | <5ppm | <5ppm |

| Chloride &bromide (as Cl) | <0.05% | <0.05% |

| Heavy metals (as Pb) | <0.001% | <0.001% |

| Iron (Fe) | <0.001% | 0.0005% |

| Stabilizer (H3PO2) | <1.5% | <1.5% |

| Sulphate (SO4) | <0.005% | <0.005% |

Industry Applications

Hydrofluoric Acid 40% is essential in several industrial processes. Commonly used for glass etching, it also plays a key role in cleaning metals and as a reagent in electronic manufacturing and specialized chemical synthesis. Its high reactivity makes it valuable for processes demanding precision and strong etching capabilities.

Safe Handling and Packaging

Due to its corrosivity and reactivity with glass and metals, Hydrofluoric Acid 40% is exclusively supplied in plastic or Teflon containers. These materials prevent dangerous chemical reactions and ensure product integrity during storage and transport, minimizing hazards to users and the environment.

Storage and Shelf Life

Proper storage is essential for maintaining stability and safety. Store Hydrofluoric Acid 40% in a cool, well-ventilated area away from incompatible substances like glass and strong bases. Airtight containers extend its shelf life to 24 months, reducing the risk of hazardous vapor emissions.

FAQ's of Hydrofluoric Acid 40%:

Q: How should Hydrofluoric Acid 40% be handled and stored safely?

A: Handle Hydrofluoric Acid 40% wearing full protective equipment, including gloves, goggles, and a chemical-resistant apron. Store it in airtight plastic or Teflon containers in a cool, ventilated area, away from incompatible materials like glass and strong bases. Immediate cleanup of spills is crucial due to its highly toxic and corrosive nature.Q: What are the main industrial uses of Hydrofluoric Acid 40%?

A: Hydrofluoric Acid 40% is primarily used for glass etching, cleaning metals, manufacturing electronics components, and serving as a reagent in various chemical synthesis processes. Its ability to react with silicates and metals is especially valued in specialized industrial applications.Q: When does Hydrofluoric Acid 40% pose the most significant hazards?

A: Hazards are greatest when Hydrofluoric Acid 40% is handled without proper protective equipment or when it comes into contact with unsuitable materials, such as glass or metals. Fumes emitted at room temperature also pose inhalation risks, making adequate ventilation and airtight storage critical at all times.Q: Where does Hydrofluoric Acid 40% need to be stored to maintain its quality?

A: To preserve its stability and extend shelf life, Hydrofluoric Acid 40% should be kept in a cool, ventilated, and dedicated chemical storage area-always within airtight plastic or Teflon containers and far from incompatible substances like glass, metals, and strong bases.Q: What is the process for disposing of Hydrofluoric Acid 40% safely?

A: Disposal of Hydrofluoric Acid 40% must comply with local hazardous waste regulations. Transfer residual acid to designated hazardous waste containers and coordinate with licensed disposal professionals to neutralize and treat the waste, preventing environmental contamination and health hazards.Q: How does Hydrofluoric Acid 40% benefit specific industrial applications?

A: Hydrofluoric Acid 40% is uniquely capable of etching glass and dissolving oxides on metals, making it indispensable for precise glass artwork, microfabrication in the electronics industry, and cleaning specialized equipment in manufacturing settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Purity Acids Category

BENZIMIDAZOLE CHEMICAL

Classification : Organic Acids

Melting Point : 171175C

Purity : 98% min

Boiling point : 360C

Raw Material : oPhenylenediamine

EINECS No : 2000814

ACETIC ACID GLACIAL FOR HPLC

Classification : Other, Organic Acid

Melting Point : 16.6C

Purity : 99.8% Min (GC)

Boiling point : 118C

Raw Material : Acetic Acid Glacial

EINECS No : 2005807

Orthophosphoric Acid AR

Classification : Other, Inorganic Acid

Melting Point : 42.35 C

Purity : AR Grade, 85%

Boiling point : 158 C (decomposes above this temperature)

Raw Material : Elemental Phosphorus or Phosphate Rock

EINECS No : 2316332

Hydrobromic Acid 47%

Classification : Other, Inorganic Acid

Melting Point : 11C

Purity : 47%

Boiling point : 125C

Raw Material : Bromine, Hydrogen

EINECS No : 2331130

"Only deals in retail accepting orders upto 500ml only".

|

ALPHA CHEMIKA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry